Creating the Bugaboo Atelier collection

We take you inside Bugaboo’s atelier where our products are crafted – from concept to creation.

Trends and insights

Our design process begins with research and experimentation – looking at trends, trying new things, thinking differently and pushing the limits of our knowledge. We consider all possibilities, but eventually are very selective, finding the best combination of fabrics, hardware, patterns and sewing techniques.

During the search for inspiration, stylists and designers consider what parents worldwide are interested in. After all, the stroller is an extension of the person who drives it. Whatever the team sets out to create, it needs to be relevant for both for men and women. Basic colors like black and white are globally recognized as elegant and attractive.

The first inspiration for the Atelier collection came during the trip to fabric trade show Première Vision in Paris. Stylist Barber Ebbinge said during the trip her team thought deeply about the longtime success of French fashion houses like Isabel Marant and Chanel: “We were really taken by classic combinations of simple colors that stand out. Their looks have something modern, yet hint to a style that’s timeless, maybe even something you’d call old-fashioned. But it works really well. These brands don’t follow trends, they set the trends. We knew we were designing for a limited edition, meaning the production run will be smaller quantities than a standard model. The Atelier collection, like our other limited edition strollers, is intended for parents who want something different than others have.”

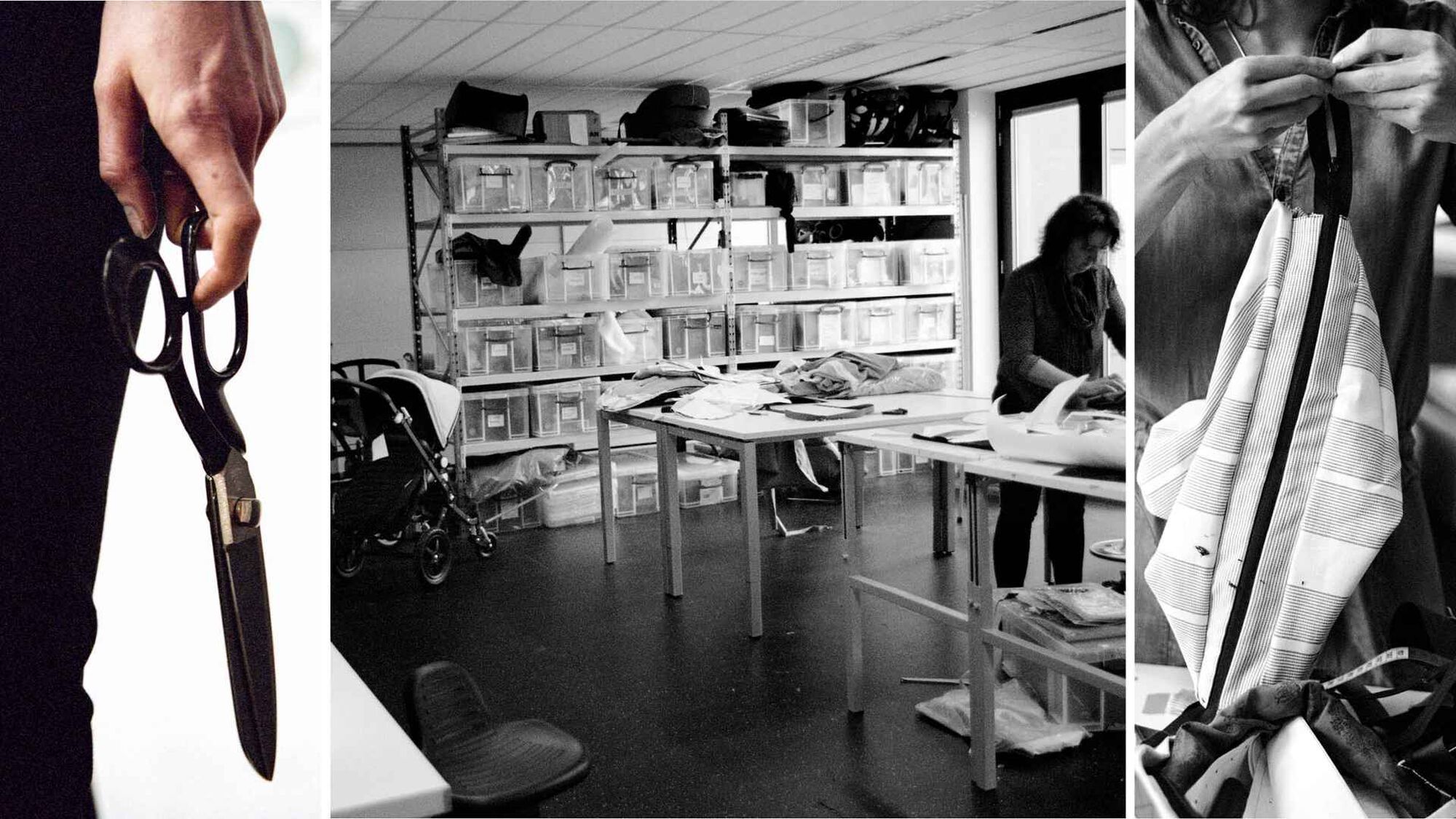

Measure twice, cut once

The second step in our design process is producing a sample – where ideas that started on paper really come to life. Every element means something. Quality is of the utmost importance, so there is painstaking attention to every detail. Our designers uphold the highest standards in order to please the most critical eyes.

The team regroups at headquarters in Amsterdam, and starts to pin fabric samples on the stroller chassis inside the atelier. With twenty years of experience to draw on, the team is aware of what works and what doesn’t in terms of fabrics. We continue to tweak and transform the stroller to make something totally new.

Barber explains: “We wanted a chicer look for the sun canopy trim, something that would coordinate very well with the woven stone mélange fabric. We considered several options before we came to black leather-look. We also knew the underseat basket would look best in black, but when we first saw it on the stroller - we thought ‘this looks boring’. We added trim in stone mélange to the Bugaboo Cameleon3 Atelier, as a sort of mirror image to the trim on the seat. Then we saw the strong silhouette we were looking for, that striking contrast between black and white.”

Stylists like Barber work together with fabric engineers to evaluate the stroller’s construction. Each step in creation, each stitching technique and each fabric panel goes under a magnifying glass. It’s not just the look of sample that needs to be perfect, but all of the components and processes need to be ready for the stroller to go into production.

The finishing touches

The last step in our design process is assembling the sample. Our designers critique their labor of love before it goes into full production. It needs to look and perform perfectly. Technique, design, function and form must seamlessly come together – craftsmanship is what brings us from concept to creation.

Iris Zhang, a fabric engineer in Xiamen, manages the translation of critical product requirements to the seamstresses in the sample room. The techniques created in the Amsterdam atelier are applied in the Xiamen atelier, bringing to life special details in the hand-sewn stroller fabrics and handlebar grips.

The first production run answers the question- “Can the production line deliver on what the designers have created? Will creating the stroller in this way produce the best quality?” Since we have exceptionally close contact with our suppliers and do all the production in house, we can try out new things. This synergy makes us able to reach quickly to changes and anticipate consequences.

The samples are then sent to functionality testing. Can fabrics and materials pass tests for strength and durability? Can zippers open and close thousands of times? If negative results come out of those tests, then we have to make changes even though we’re in love with the look. We want the stroller to be beautiful, but also meet all of the necessary safety requirements.

Fabric engineer Marieke Borkent collaborates with Bugaboo’s production facility in Xiamen, China. “We are very precise about what we accept in terms of quality. We’re constantly improving on our own standards. We check and critique everything, even those little details you think no one would notice. That’s really putting on the finishing touches to create a perfect stroller.”